We introduce ourselves as a leading manufacturer of Spray Drying Plants for various products in different industries. Fabricated under the close surveillance of our expert professionals, these spray drying plants deliver precise end results in detergent industries. Our range of spray drying plants includes laboratory spray dryers, drying chambers, rotary atomizer, two fluid nozzles, pressure nozzles etc.

Item Code: LSD-01

Item Code: LSD-01

The Laboratory Spray Dryers is a totally self contained unit and is supplied ready for immediate operation. The laboratory spray dryers unit is compact and can be kept on a table top or bench. The solution or suspension is converted to powder in a single operation. The unit can be used to establish new products/processes as the quantity of sample required is small, only 50 to 100 ml.

Construction:

• The blower, electrical air heater, air compressor and the pump are placed in a stainless steel panel, with free and easy access

• The air entering the panel is filtered through a fine cloth filter

• The chamber and cyclone are of borosilicate glass with clamp fittings, designed for easy assembly and removal

• The peristaltic pump is mounted on the front of the panel with easy accessibility

Technical Information:

• Evaporation rate of water at inlet temperature of 250°C is approx 1500 m/ hr

• Air inlet temperature range: up to 250 ac

• Heater capacity: 3 kwh

• Spray system: 2 fluid nozzle

• Spray/ hot airflow: downward co-current/ upward counter co-current

• Air compressor: inbuilt

• Power supply: 230 V-50 Hz, 15 amps

Dimensions: 700 x 600 x 450 mm (h) (w) (d)

Application:

They have various application areas, such as used in Plastics, Ceramics, Pharmaceutical products, Bio-chemicals, Herbal extracts, etc.

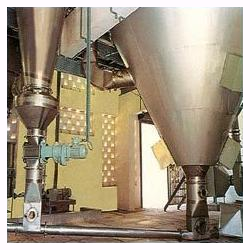

We have designed Spray Drying Systems that is also based on single stage operation and extensively used to convert solutions, suspensions and slurries into dry powder within a few seconds without any intermediate handling. These dryers are suitable for drying heat sensitive materials due to the rapid speed and proper temperature. Further, these are also provided with rotary atomizer, a pressure nozzle or a two fluid nozzle to ensure effective atomization.

We have designed Spray Drying Systems that is also based on single stage operation and extensively used to convert solutions, suspensions and slurries into dry powder within a few seconds without any intermediate handling. These dryers are suitable for drying heat sensitive materials due to the rapid speed and proper temperature. Further, these are also provided with rotary atomizer, a pressure nozzle or a two fluid nozzle to ensure effective atomization.

Features:

• Easy to handle

• Highly effective

• Superior functionality

We also offer a wide range of Pressure Nozzles that generates energy for atomization which is applied solely by the feed liquid pressure. These pressure nozzles are available with single swirl chamber to minimize plugging and can also be fabricated in various specifications to suit the varied requirements of the clients.

We also offer a wide range of Pressure Nozzles that generates energy for atomization which is applied solely by the feed liquid pressure. These pressure nozzles are available with single swirl chamber to minimize plugging and can also be fabricated in various specifications to suit the varied requirements of the clients.

These pressure nozzles systems are provided with:

• Nozzle Body

• Orifice Seal

• Orifice Disc

• Swirl Chamber

• Chamber End Plate

• Body Seal

• Female Adopter

We export atomization by Two Fluid Nozzles that is carried out with a rotary atomizer and a pressure nozzle or a two fluid nozzle. the system is provided with two fluid nozzles where compressed air supplies most of the energy required to atomize the feed liquid. the process is used in laboratory and small plants to produce fine powder.

We export atomization by Two Fluid Nozzles that is carried out with a rotary atomizer and a pressure nozzle or a two fluid nozzle. the system is provided with two fluid nozzles where compressed air supplies most of the energy required to atomize the feed liquid. the process is used in laboratory and small plants to produce fine powder.

Features:

• High tensile strength

• Robust construction

• Easy operation

We also offer an array of Rotary Atomizer that are used for drying various liquids in several industries. These rotary atomizers are enabled with atomizer wheel that rotates at a high speed and ensure disintegration of the material into fine droplets. These are used to handle wide range of products including slurries with high viscosity.

We also offer an array of Rotary Atomizer that are used for drying various liquids in several industries. These rotary atomizers are enabled with atomizer wheel that rotates at a high speed and ensure disintegration of the material into fine droplets. These are used to handle wide range of products including slurries with high viscosity.

Features:

• Robust construction

• High functionality

• Easy operation

We also specialize in the sphere of installing Drying Chambers that has high capacity and equipped with line vibration fluidized bed dryer for even heating of the material. The drying chambers system saves 30% of energy due to the advanced technology used for its fabrication.

We also specialize in the sphere of installing Drying Chambers that has high capacity and equipped with line vibration fluidized bed dryer for even heating of the material. The drying chambers system saves 30% of energy due to the advanced technology used for its fabrication.

Some of the features of the systems are:

• It is stable in operation

• Convenient in maintenance

• Low noise

• Long life

Operation:

• Stable fluidized state ensuring no dead angle and phenomenon of broken out

• No damaging of the surface of raw material

• Can be used for drying raw materials that are easy broken

• Unaffected from the anomalous shape of the raw material

• Effective to prevent cross pollution between raw material and air

• Clean environment of operation

• Suitable for all kinds of press tablet and granule, boric acid, borax, maleic acid, lees, mono sodium granule, edible sugar, edible salt, mine residue, bean, and seeds

We offer a wide an extensive range of Pilot Dryers that is proven planning tool and used to scale dehydration plant. These pilot dryers are fitted with highly qualitative heavy duty components as a full sized system. Available for long and short term lease, our pilot drying system is used to make changes to production drying applications without risking substantial capital.

We offer a wide an extensive range of Pilot Dryers that is proven planning tool and used to scale dehydration plant. These pilot dryers are fitted with highly qualitative heavy duty components as a full sized system. Available for long and short term lease, our pilot drying system is used to make changes to production drying applications without risking substantial capital.

Features:

• High tensile strength

• Robust construction

• Easy operation

• Smooth functionality